Image Source: Getty Images

Carpentry has always been about skill, precision and pride in the work. However, like the rest of the construction industry, the tools and methods we use are changing fast. From digital blueprints to smart project management, technology is reshaping how carpenters plan, build and learn.

These changes bring huge potential to improve efficiency, reduce waste and make the job safer and more rewarding but they also mean carpenters need the right support to keep pace.

From Paper Plans to Digital Design

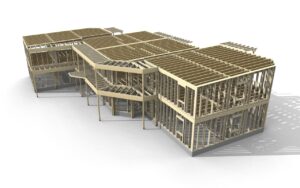

Image Source: https://vertexcad.com/bd/for-wood-framing

Traditional plans on the drawing board are giving way to computer aided design and 3D modelling. This shift can allow carpenters to map out projects in exact detail before a single cut is made. Being able to visualise a structure from every angle improves accuracy, avoids costly errors and helps clients better understand the build from the start.

Smarter Tools, Prefabrication and Automated Equipment

Image Source: https://www.pbctoday.co.uk/news/mmc-news/modular-construction-guide/44042

Automation is starting to play a bigger role in carpentry, particularly on large scale or repetitive projects. CNC machines and robotic tools can handle cutting and assembly with precision and speed. Many crews are now also turning to prefabricated framing to reduce time and labour on site. These systems allow key elements to be built off site in a controlled environment, then delivered and assembled with greater speed and consistency. For carpenters, this frees up time for more specialised or detailed work, and helps keep projects moving even when labour is tight.

AR and VR Training and On Site Support

Image Source: https://heavyequipmentcollege.edu/how-virtual-reality-help-construction-safety-training

Augmented and virtual reality are beginning to make their mark too. AR helps carpenters overlay digital measurements onto a physical space, which can be handy for adjustments and layout checks. VR is proving valuable for training, offering safe and realistic environments to practise tasks before heading to site. With many trade schools now implementing this as part of their training plans.

Sustainable Practices Backed by Tech

Image Source: https://www.sipeurope.eu/en/se-sip-construction-system/using-sip-system/prefabricated-buildings

Technology is also helping the trade become more sustainable. New materials, smart waste management systems and tools that track usage all make it easier to reduce waste and lower a project’s impact. Many carpenters are also starting to use recycled timber, low emission products and non-toxic finishes to meet growing client demand for greener builds.

Better Project Management and Communication

Digital tools now help manage jobs from quote to completion. With mobile access to plans, timelines and material lists, carpenters and clients can stay on the same page. These tools also make it easier to allocate resources, track costs and deliver on deadlines, reducing stress and improving results across the board.

2 Responses

Jojobet5669 is solid! Never had any issues with payouts and their customer support is actually really helpful. Worth a shot if you’re looking for a new spot. Might just be your lucky number! jojobet5669

Just signed up on jjlo3. Let’s see what this is all about! Anyone have any tips or recommendations for a newbie? jjlo3